Is Corque Portugal's most valuable resource?

by: Core77, 2012-02-06 08:00:00 UTC

This isn't the first time we've talked about Corque on Core77, and since the Portugese design brand keeps coming up with one good idea after another, it won't be the last either. Corque was born in 2009 after its founding partners finished a three-year research and development program that explored the sustainability of using cork as a material for more than just wine bottles. What they learned in a nutshell? Cork is a renewable resource; It grows on trees, or rather, it is trees. But because it regrows only every nine years, harvesting it is a delicate process, one that requires highly skilled workers. [Ed Note: For more on cork harvesting and manufacturing, check out Daniel Michalik's series on the material!] Most of the world's cork comes from Portugal, 52.5%, to be exact, making it an ideal material for a Portugese design team like Corque to utilize. And it doesn't hurt that it makes for furniture so beautiful furniture it crosses the line between art and object.

(more...)

Nokero's Portable, Practical Energy Solutions

Nokero's Portable, Practical Energy Solutions

by: Core77, 2012-02-06 16:00:00 UTC

Finally, a convenient, realistic and affordable way for the average consumer to utilize solar power: Nokero's C110 Battery Charger, which runs 14 bucks (battery included) and works with any rechargeable AA, not just the company's own. "Simply insert a rechargeable AA battery into the back of the C110 and set it out in the sun," the company explains. "In a matter of hours, your battery will be charged."

Nokero, which is short for "No Kerosene," also produces the super-economical N100 and C77 2011 Design Awards 20 Notable N200 Solar Lights, meant to replace the kerosene lamps used in developing nations. Their research indicates that a child using a kerosene lamp to study by is exposed to fumes commensurate with a two-pack-a-day smoker. The $15 N100 and $20 N200 run completely clean, using solar power to juice up the same AA battery found in their C110 charger, and they're dead-simple to use: Hang them in sunlight, then turn them on when it gets dark.

Nokero was founded in 2010 by inventor Steve Katsaros "to develop safe, affordable and environmentally-friendly technology that eliminates the need for harmful and polluting fuels used around the world." Check out more of their stuff here.

(more...)

Living Future 2012: Women Reshaping the World

Living Future 2012: Women Reshaping the World

by: Sustainable Design News, 2012-02-06 00:23:05 UTC

The International Living Future Institute announced its keynote speaker lineup for its sixth annual Living Future unConference.

The International Living Future Institute announced its keynote speaker lineup for its sixth annual Living Future unConference.

A sold-out event since 2009, this year's theme, "Women Reshaping the World," is rapidly gaining traction as the must-see program for green building practitioners and sustainability-focused thought leaders.

Bento Chair and Table by Form Us With Love

Bento Chair and Table by Form Us With Love

by: mocoloco, 2012-02-02 21:44:45 UTC

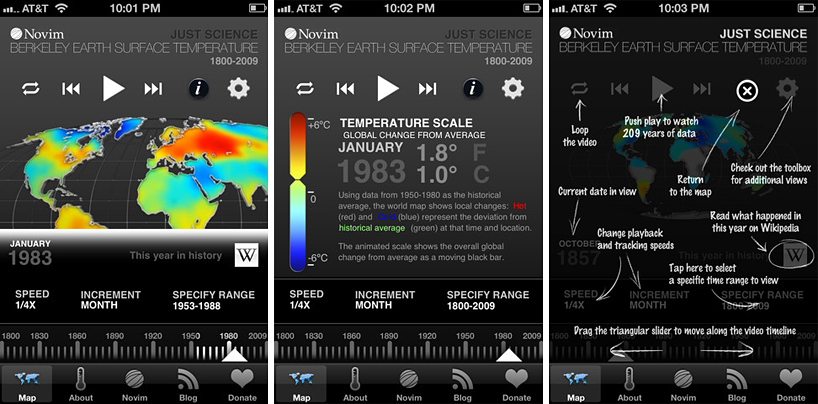

just science climate change app

just science climate change app

by: Designboom - Weblog, 2012-02-05 17:12:00 UTC

the app for iPhone and iPad suggests a way to bring scientific research into public discourse by presenting the results of the expansive 'berkeley earth surface temperature' study in a visually interesting, interactive way.

read more

Humpback whales inspire better helicopter rotor blades

by: Gizmag Emerging Technology Magazine, 2012-02-03 20:59:14 UTC

Oh, those humpback whales and their weird fins. First, they inspired more efficient

wind turbines. Next, their unique qualities were copied by

undersea turbines used to harness tidal flow energy. Now, they’ve led to rotor blades that allow helicopters to be more maneuverable. It all comes down to bumps along their leading edge, known as tubercles...

Continue Reading

Humpback whales inspire better helicopter rotor bladesSection: Aero GizmoTags: Aerodynamics,

Aircraft,

Biomimicry,

Helicopters,

Whale

Related Articles:

Eco friendly shoes for those who want a greener footprint

Eco friendly shoes for those who want a greener footprint

by: Ecofriend, 2012-02-04 13:18:40 UTC

Garima Goel:

For those who want to reduce their ecological footprint and do their bit for the Mother Nature with every single step they take, what could be better than a pair of eco friendly shoes? Many companies in the market are now dealing in a range of stylish eco friendly footwear to make sure that the buyers do not sacrifice on comfort or style, while opting for green shoes. Taking into consideration the number of shoes made and worn throughout the world every year, you can well imagine the impact your choice will have on reducing carbon footprint.

Eco friendly packaging designed to reduce waste

Eco friendly packaging designed to reduce waste

by: Ecofriend, 2012-02-03 10:49:14 UTC

Sonia Renthlei:

The world is now taking green living seriously in view of the increased damage being caused to the environment. Manufacturers of consumer products are looking at eco friendly resources for producing goods and are also utilizing what is known as eco packaging to market their products. These packages made from biodegradable materials are replacing plastic and metal rapidly. If every manufacturer joins the bandwagon, we may soon see the world get rid of plastic, leaving the earth cleaner and healthier.

Open Privy waterless toilet helps add to precious top soil

Open Privy waterless toilet helps add to precious top soil

by: Ecofriend, 2012-02-03 12:20:00 UTC

Sonia Renthlei:

Many innovative creations are yet to see the light of day despite being practical and forward thinking. Funding is one major issue, curbing their designs. Luckily, there are organizations and foundations that seek to give creative people a platform where ideas can be generated and, hopefully, come to life. We recently stumbled onto a handy concept entered as part of the James Dyson Foundation Award. Presented as Austria’s entry, it is called Open Privy and envisions a waterless toilet system that is easy to use and eco friendly.

Open Privy- the top soil lodge

Picture Gallery

Open Privy- the top soil lodge

Most toilets are designed for use indoors and require a lot of water to flush. This can be a problem if you live in areas where water is scarce. The waterless toilet is based on the Bukashi method of composting. Open Privy can be installed in the outdoors or in the bathroom. If it’s placed in the open, rainwater can be collected and allowed to filter down to a downpipe. Bent metal and willow sticks have been woven to cover the toilet and guard against weathering. A hinge that connects the toilet’s inlay, seat, downpipe and cover masks the smell, letting air circulate freely.

Open Privy serves as a good method of composting and enhances the top soil effectively to act as a natural fertilizer. Users can choose to either throw away the excrement collected or reuse it in the composting process. Ideal for use in places where water isn’t in abundance, Open Privy is also a solution to those disadvantaged areas that cannot afford to build water-guzzling toilets.

The toilet has been built such that it can be dismantled which serves as the perfect solution for rehabilitation centers in times of natural and man-made disasters. Easily maintained and hygienic, we‘re hoping that Open Privy will soon be mass produced.

Via: JamesDysonAward

Peep the Technique: "FACETURE" by Phil Cuttance

Peep the Technique: "FACETURE" by Phil Cuttance

by: Core77, 2012-02-04 00:00:00 UTC

All photos by Petr Krejci

All photos by Petr Krejci

Seeing as he cut his teeth with the likes of Max Lamb, Studio Gilthero, Martino Gamper and Julia Lohmann, it comes as no surprise that designer Phil Cuttance is well-versed in materials and processes. "FACETURE" is a series of household objects that take a vaguely crystalline appearance based on a unique fabrication process. Each vase, lamp and side table looks is made by casting a water-based resin in a handmade mold:

First the mould of the object is hand-made by scoring and cutting a sheet of 0.5mm plastic sheet. This sheet is then folded, cut and taped into the overall shape of the product that is to be cast. The mould's final shape, and strength, is dictated by which triangular facets I pop in and out. I do this each time I ready the mould for the next object, meaning that no two castings are the same. I then mix a water-based casting resin that is cast in the mould where it sets solid.

The resin is poured into the hollow mould and rolled around to coat and encase the sides, controlled by me on the casting jig on the machine. The material soon sets creating a hollow solid object. Then another, different coloured measure of resin is poured into the same mould, and swirled around inside, over the first. When it has set, the mould is removed to reveal the solid set cast piece.

The results look something like stalagmites from a virtual cave, though Cuttance notes that their origin is neither geological nor digital: "The casting appears with sharp accurate lines and a digital quality to its aesthetic, a visual 'surprise' considering the 'lo-fi,' hand-made process from which it came."

But the real gem is the bespoke machine with which Cuttance creates "FACETURE":

(more...)

Comments by our Users

Be the first to write a comment for this item.