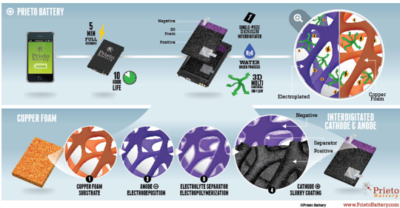

Amy Prieto, Colorado State University assisting professor, re-imagines the lithium-ion battery in a 3D solid state form, with no liquid electrolyte at all. Instead,a nanowire structure forms the backbone, with the anode, cathode, and electrolyte material all coated on top using a similar electroplating process as the tin solution above.

The nanowire increases the surface area for the lithium ion movement to take place; the shorter distances between the components means that charges generate very quickly — 3 minutes for a complete charge.

The anode in a Prieto battery is different, too. Instead of graphite, Prieto uses copper antimonide, a compound that stores more lithium per unit of volume than graphite does. All told, a Prieto battery is projected to last 10 full hours and completely charge in 3 minutes. An early prototype made with slightly different materials lasted 750 charging cycles before dropping to 80 percent of the total charge capacity compared to traditional lithium batteries in 350 charges. The final battery blueprint calculates that a Prieto battery will last 30 percent longer than a conventional battery.

Prieto looks to commercialization in 18 months after they license the patent-pending architecture to other manufacturers.

And what we like: a Prieto battery doesn’t call for clean rooms and the only acid it uses is citric. “You can dump it down a sink” according to Prieto. And that helps to keep the pricing low.

Summing up the advantages:

Battery Performance High power density

Rapid charge: 3 minutes vs. 20 minutes

Long life: upto 30% longer

Smaller package: 1/2 to 2/3 the size for the same energy density

Battery Manufacturing Process has lower cost than traditional methods: $250 per kWh vs. $600+ per kWh

Environmentally friendly: Water-based process

Highly repeatable: Electrodeposition is extensively used in the semiconductor industry

Easily scalable

Comments by our Users

Be the first to write a comment for this item.