Swiss manufacturer ABB has revealed a prototype robot called Frida that's designed to be dexterous enough to replace a human being on a production line. It's a good thing that'll alleviate employee shortages, not subjugate the human race.

Swiss manufacturer ABB has revealed a prototype robot called Frida that's designed to be dexterous enough to replace a human being on a production line. It's a good thing that'll alleviate employee shortages, not subjugate the human race.

Frida stands for Friendly Robot for Industrial Dual-arm Assembly, and the whole concept is pretty interesting. ABB, which is an industrial heavyweight, has reimagined the industrial robot, which is typically a huge, heavy piece of kit that's expensive, not particularly flexible and too dangerous to position near human workers. Instead of the typical single, powerful robot arm with multiple degrees of freedom, ABB considered how a typical human works in their workspace at an industrial task and tried to create a robot that could work like this. ABB also priortized making the robot cheaper, thus introducing robots to smaller companies that are robot-free.

Frida's arms have almost the same extension as a small-sized person, and while their dexterity is designed to match how human joints move, it can obviously surpass human motion limits at will--no person can spin their wrist 720 degrees, at least not outside the bounds of a horrible industrial accident. It's also lightweight and designed to be clamped to a workbench and easily moved from its station, hence the built-in handle. To make it safe, its metal body is padded, and its motor drives have limited power so that if they do accidentally encounter a squishy human they won't cause too much damage. There's also software-based collision detection to prevent things getting to this point. It's smooth, with internally routed cables, so it's easy to keep clean. And there are few "pinch points" that a curious human digit could get trapped in.

[youtube 70V6J4Y8hnc]

ABB has made an effort to note it doesn't see robots like Frida stealing jobs in the future--it's designed to work alongside people, and could be very useful when a production line process changes and a reprogrammed robot could be retrained faster than a human worker. But it's easy to see a future in which robots like Frida drop in price and increase in intelligence to the point they actually do replace humans on production lines, since they can also work 24-hour shifts, won't go on strike, or cause other social problems. And for industries like electronics manufacturing, where there's a risk of being exposed to noxious chemicals, who wouldn't prefer to see robots working in those jobs?

To read more news like this follow Kit Eaton on Twitter, and Fast Company too.

Palo Alto Research center (PARC) at Xerox have come up with a new mechanism that will increase the storage capacity of normal lithium-ion batteries by almost 40%. They achieved this challenging feat by printing the electrode in parallel with a highly conductive membrane. The type of membrane used is a closely guarded secret though.

But the work is far from finished. Some problems regarding the batteries conduit capability & effects of the technology on the battery’s life still needs to be figured out. But this achievement of PARC is undoubtedly a breakthrough in this field. The technology, if proven successful, can revolutionize the transport industry by creating affordable clean & green electric vehicles.

Similar research have been going on in this field is being carried out by various other organizations including the United States’ Department of Energy (DoE). the DoE have set itself a timeline of 2014 for reducing the cost of batteries by 70%. Automobile giant NIssan have also been working on similar technology. Their all-electric Nissan Leaf vehicle battery costs around $1000 per Kilowatt hour (kWh) which is still on the expensive end of battery costs. DoE plans to bring it down to $350 per kWh. But given the complexity of the technology, right now it looks highly unlikely that DoE will be able to meet its target of 2014.

Seemingly happy at this achievement of PARC Mr. Scott Elrod, PARC’s Director of Cleantech Innovation Program, was quoted by the media as saying that they hope to achieve a electrode thickness of up to 500um. It has been said that the technology is similar to that of printed solar cells.

Via: Treehugger

In this modern world when technological breakthroughs have seized to surprise or shock us, the word “independent existence” has found a yet another new meaning. We have already witnessed how both the teenagers and octogenarians consider it personal insult if one tries to help, assist, lend a hand to them and are always out there to pant, scream and sometimes even prove that they don’t need no help. Now, giving a new twist to this whole “I can do it myself” syndrome, we have a table lamp joining the bandwagon. The new entrant claims that it can function independently (Phew! How many times have we already heard that one). The Zen lamp doesn’t believe in electric sockets and sunshine to recharge itself. All it needs is the will to do so!

Jokes apart, the makers of the Zen light, still in the nascent stage of development, actually claim that it does not need any external source to light itself. It actually depends on the “magnetic engine” that the lamp is already equipped with. The way this lamp functions is both simple and intriguing. The magnets placed inside the lamp make sure that they create enough force to keep the lamp spinning. Now this spinning, in return, powers a series of LED diodes. The power thus generated helps the lamp light up without any external assistance.

The designs shown so far are sleek and very contemporary.

Just while penning this down, here is an afterthought. Since the idea is so simplistic and basic in nature, could we not adapt it (in its cheaper version of course!) and use it to light the kerosene-lit, forest-covered areas that still darken the world map of the 21st century.

Via: Yanko Design

Modern life with all its nano ingenuity and hi-tech expertise has time and again turned back to ancient concepts to gain inspiration to walk ahead. Similarly, the ancient art of origami has stimulated designer Chengyuan Wei to create a chic and hi-tech handset phone ahead of the normal industrial harvest.

Coordinating the minimalism and efficiency of paper origami to modern nano-technology, Hangzhou, China based Chengyuan Wei has designed the Origami Phone out of paper. The phone transforms from a flat surface to a tri-dimensional object adequately fitting into the hand when picked up to dial or answer a call. The concept is more like a pop-up set that starts out as a flat sheet of paper but when pressed on the sides revolutionizes itself to a handset.

The relevant items in a handset usually takes up a minimum space within and this was designer Wei’s raison d’être for looking for a lightweight and handy alternative.

A design and art graduate of Zhejiang University, China, Wei is currently a project participator of Product Innovation and Engineering Center, Zhejiang University.

Via: Weii Design/Technabob

Walmart, that bastion of cheap food, clothing, and everything in between, has corporate-responsibility goals that put every other big box retailer to shame. When Walmart asks its 60,000 suppliers to shape up, the world listens; a demanding packaging goal will have companies the world over scrambling to fit the requirements (for both Walmart and the inevitable copycat retailers that jack up their requirements later). In Walmart's 2011 Global Responsibility Report, we get a glimpse at just how far along the company is in meeting its ultra-ambitious goals. It's making exceptional progress.

Goal: Reduce our global plastic shopping bag waste by an average of 33% per store by 2013 (2007 baseline)

Convincing people to part with their beloved plastic bags is no small feat (outside of San Francisco, of course, where bans are a way of life). But Walmart has managed to do it. In 2010, the retailer cut down on plastic bag waste across its global operations by approximately 3.5 billion bags. This is a 21% reduction from the company's 2007 baseline--meaning the 2013 goal isn't out of the question.

In some California locations, Walmart is experimenting with nixing single-use plastic bags altogether (and offering reusable bags for a price)--a measure that is saving materials for Walmart and, to a degree, pissing off the locals (and biting Ikea). Now imagine if Walmart extended this plastic bag ban to all of its stores. At first, customers might riot. But the power of Walmart's ubiquity is that eventually, this ban could shift the average customer's mindset; this new breed of Walmart customer might bring reusable bags for every shopping trip, even outside of the big box retailer. This wouldn't come close to eliminating the plastic vortex currently floating in the middle of the Pacific Ocean, but it would be a start.

Goal: We will partner with suppliers to improve energy efficiency by 20% per unit of production in the top 200 factories in China from which we directly source by 2012 (2007 baseline).

Believe it or not, Walmart has already managed to achieve this goal (with a little help from the Environmental Defense Fund). An impressive 119 factories have improved their efficiency by 20%--but the EDF told us recently that Walmart's goal isn't ambitious enough. The organization believes that in many cases, factories can cut down on energy use by up to 60% with simple fixes. Unfortunately, Walmart asking its Chinese suppliers to increase energy efficiency probably won't inspire a sea change anytime soon; the EDF has had to deal with skepticism (initially, at least) during many of its factory visits.

Goal: In the U.S., Walmart will double sales of locally sourced produce, accounting for 9% of all produce sold by the end of 2015.

This goal, announced in October 2010, is still "in progress," according to Walmart. The chain says that it will measure success based on the amount of produce sales within the state of origin versus overall dollar amount of produce sales. We think Walmart can reach this goal purely because it has the cash resources to do so. In October, the company explained that it intends to go so far as to expand cash crops in certain regions. In Mississippi and Arkansas, for example, Walmart is using its hulk-like size to convince farmers to switch from tobacco and cotton (there is declining demand for these crops) to blueberry farming. If Walmart wanted, we imagine, it could go far beyond a 9% goal just with the promise that farmers growing certain crops will get business from the company. And this, needless to say, could change the crop landscape across the U.S. to include foods that are suited to the local climate. Still, we don't expect to see the people with "Buy Local" bumper stickers hitting up Walmart anytime soon.

Walmart's goals seemed almost too ambitious when they announce them. But never question Walmart; some of the goals might not have even bee ambitious enough. Either way, Walmart wins. Cutting down on waste, increasing energy efficiency, and ramping up sales of local produce will save the company on fuel, energy costs, and materials--and in the end, make Walmart even more powerful than it already is.

[Photo from Flickr user Koonisutra]

Reach Ariel Schwartz via Twitter or email.

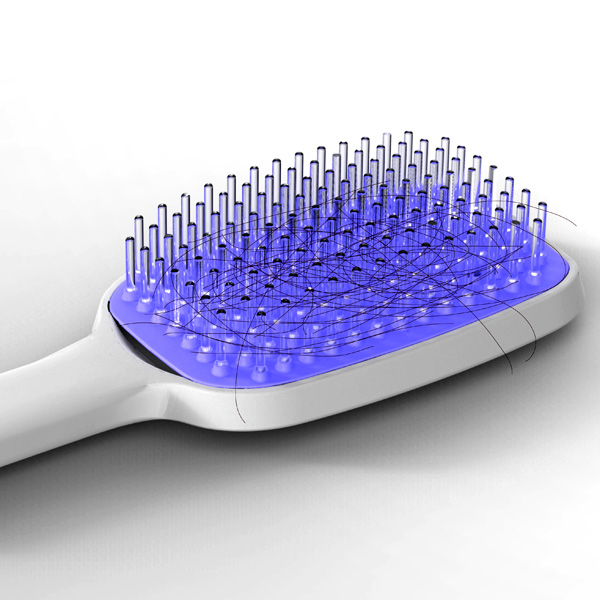

Let’s get paranoid for a minute. Worried someone might steal a strand of your hair and clone you? With the Easy Comb and its removable rubber base, DNA snatchers are kept at bay and your brush stays clean. Seriously, someone should have thought of this a long time ago. I’ve seen similar concepts but this one seems to be the most basic and sometimes that’s the best way to go.

Easy Comb is a 2011 iF concept design entry.

Designer: Juhyun Lee for KOI & Insix Design Studio

----------

Yanko Design

Timeless Designs - Explore wonderful concepts from around the world!

Yanko Design Store - We are about more than just concepts. See what's hot at the YD Store!

Milan 2011: industrial designer Konstantin Grcic launched this armchair inspired by windsurfing and paragliding equipment for design brand Vitra at the Salone Internazionale del Mobile in Milan. (more…)

Milan 2011: Swiss brand Punkt. presented this alarm clock by British designer Jasper Morrison at Spazio Rossana Orlandi in Milan last week. (more…)

What’s happening right now?

Previously we had talked about how transportation infrastructure has always been a major part of our modern economy. And as with other important industries how it does consume massive quantities of energy as well as emanates high levels of carbon emissions. Well, this is where the green vehicles come into the picture, literally as the zero emission saviors of our eminent automotive industry. Now green cars can be categorized by their fuel efficiency, mode or even manufacturer, but green cars composed from sustainable, green materials should certainly be classified as a distinct class altogether. They seem to be the only vehicles to imbibe that unique essence of total sustainability with their entire propensity.

Trends:

1. Toyota develops hybrid car made of seaweed!:

Yes you have read that correctly and it may seem baffling, but it is very true. Named as the 1/X, this hybrid car concept will be composed of derivatives of seaweed fused with carbon-fiber reinforced plastic for body strength. To be endowed with a 500cc engine, the car will be a smaller cousin to the Prius (the engine being about 1/3 of its size) with a weight of just over 400kg.

2. Ford’s green hybrids get sustainable interiors:

In a righteous bid to lower our carbon dioxide emissions by a whopping 5 million pounds, Ford has ingeniously come up with natural soya-based cushion foam for their car seats, which would also be draped in recyclable fabric. This in effect nullifies the usage of conventional polyurethane foam derived from non renewable petroleum. The ambitious plan entails that around a million cars are to be furnished with such ‘naturalistic’ seats. And as a side note Ford is looking forth to adopt other sustainable elements like bio-plastics and bio-resins for their car components.

3. A high-performance green car, 95% biodegradable:

Researchers form Warwick University has adroitly conceived this fascinating piece of contraption, and in our experience it becomes the closest thing to being described as ‘nature on wheels’. The vehicle has tires made of potatoes, brake pads from ground cashew shells, body from hemp and rapeseed oil; and if that was not enough it uses fuel made from fermented wheat and sugar beet! And wait, don’t be fooled by all those ‘crops’, here is the good part; the car can actually spurt to a high speed of 150mph and has a mileage of 35mpg.

4. Sunbeam Tiger Concept - a complete green ride for the future:

Okay this one’s a little on the conventional side, but the design elements remain as remarkably practical as ever. The main chassis is composed of recycled aluminium with integrated rollover protection for the user, while the body panels are made from hemp fiber and are eco-painted as well. And it’s not only about the looks, notching a ‘green’ level up, soya foam cushions have been introduced onto the seats, and too covered in all natural bio-fabric.

5. Toyota hybrids to get green interiors with plant-based resin:

Green is literally about to become green if this conscientious proposition by Toyota ever comes to be realized. After gifting the world Prius (and that too 2 millions of it!), Toyota now plans to incorporate a newly developed plant-based resin that could be used to cover 60 percent of the interior. Maybe recycled carbon fiber on the outside and sustainable elements in the inside; now that would be our type of car.

The concept:

Green technology is advancing at such a fast and rather unique rate that we can simply co-relate it to evolving. The automotive industry has done its fair share of polluting, and in a bid to rectify that they have adopted the low emission ideal over the last decade. And now rather ascending to a much higher level they (at least some sections of the industry) are trying to endorse that ultimate dictum of energy saving and efficiency, in relation to the whole procedure, not just the sustainable end product i.e. the green vehicle.

The advantages:

As already mentioned, low emissions deal with just the end product i.e. the car itself, while adoption of green materials certainly imparts sustainability to the whole production procedure, culminating in the final design. Hence adoption of green materials in green cars logically allows for low fossil fuel consumption as well as reduced emissions. Moreover from an economic point of view cost effectiveness is an important criterion, and green cars can conveniently make that positive difference in fuel efficiency, in comparison to their gas guzzling cousins.

The impact:

A proper definition of a green vehicle suggests that it is a road motor vehicle that produces less harmful impacts to the environment than comparable conventional internal combustion engine vehicles running on gasoline or diesel, or one that uses alternative fuels. But here we are dealing with green vehicles made out of green materials, and it certainly counts more than that. The clear and rather righteous distinction in this case would be the holistic approach to sustainability. Vehicles emanating low emissions are good, but vehicles made out of sustainable elements and emitting low emissions are certainly better. Now if we equate that with their affordability, the ‘green’ impact could truly be manifold in this case.

Milan 2011: Berlin designer Jerszy Seymour presents this chair made from two continuous metal wires at the Salone Internazionale del Mobile in Milan this week. (more…)

Comments by our Users

Be the first to write a comment for this item.