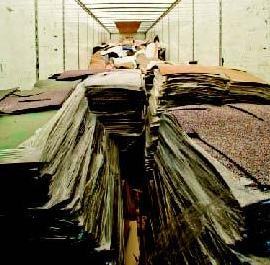

Five billion pounds of carpet ends up in landfills each year. Less than 5% of that is reclaimed. At Interflor’s carpet reclamation and recycling program, ReEntry 2.0, now reclaims all InterfaceFLOR and competitor carpet (commercial and residential, broadloom and tile) regardless of face fiber type or backing used. This program diverts waste from landfills and further reduces our reliance on virgin raw materials. In 2008 about 40 million pounds were reclaimed in this way and didn’t end up in the landfill.

How It Works: Through patent pending technology, they cleanly separate the face fiber and backing of nearly any carpet type. Separated type 6 and 6,6 nylon fiber are recycled into new 6 and 6,6 nylon, while separated GlasBac® (major part is recycled industrial and post consumer material) backing and similar competitor backings are recycled into new backing using Cool Blue™ backing technology. Interface publishes its post consumer material content of every type of carpet.

The reclaimed nylon is used in Convert™ – the groundbreaking new category of modular carpet that is manufactured with a full color spectrum of post-consumer yarn. This entire process requires less energy than other recycling processes. Plus, we’ve identified recycling partners for other reclaimed carpet materials to ensure no reclaimed carpet ends up in the landfill.

ReEntry 2.0 raises the bar for sustainable carpet products without compromising performance or aesthetics and brings it closer to achieving it’s Mission Zero™ goal of zero environmental footprint by the year 2020.

Comments by our Users

Be the first to write a comment for this item.