Researchers at Carnegie Mellon have taken on the task of walking a mile in the shoes of Product Carbon Footprint (PCF) measurement standards, in the paper (via SmartPlanet) ‘Uncertainty and Variability in Carbon Footprinting for Electronics: Case Study of an IBM Rack-mount Server.’

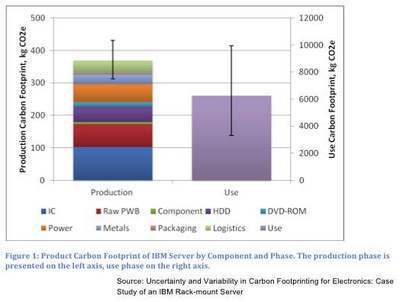

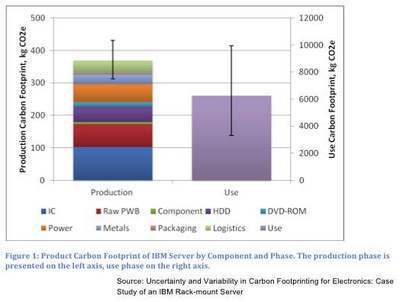

Weber’s case study of the IBM rack-mount server found that the production phase of the product was measurable with a low degree of uncertainty, but at the use phase, accounting for 94% of the total greenhouse gas emissions associated with the product, had only predictive measurements since it was not possible to clearly determine “how and for how long the product would be used.”

Additionally, Weber brings in the variability of mix in electricity markets, delivery methods and other factors to complicate accuracy of PCF studies. Altogether, his conclusions assigned a +/- 15% range for production, a +/- 25% range for the delivery phase a +/-50% range for the use phase, and +/-35% range for the cradle to grave carbon footprint.

“This finding confirmed the importance of IBM’s ongoing efforts to increase energy efficiency of its server products and the data centers where servers are used,” said Weber, since energy efficiency in the use phase is the product attribute most likely to lower the product’s carbon footprint. He also recommends that standards writers should dictate when to use regional, country or multinational electricity mixes in future PCF standards.

+/-15% margin is not an ignorable amount for a method that is already being used to set policy and make comparative environmental product declarations.

Comments by our Users

“Which does not mean there is no reason for a footprint or life cycle analysis. It is good to know where in the life cycle of a product the cost for the environment are made, either CO2, water, energy or whatever your seeks to reduce in it's environment. F”