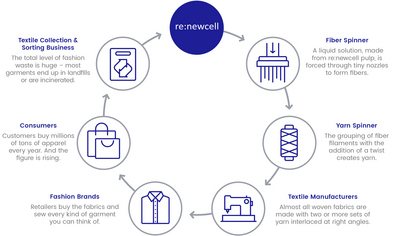

Re:newcell’s recycling technology transforms high cellulosic post consumer waste into pure, natural dissolving pulp to create new fibres. It’s an efficient process that reuses chemicals, and it’s up and running.

The discarded textiles are shredded, de-buttoned, de-zipped, de-colored and turned into a slurry. Contaminants and other non-cellulosic content are separated before it is dried to produce a pure, natural pulp, which is packaged into bales and fed into the textile production cycle.

Tests have compared textile fibers made from Circulose pulp with textile fibers made from dissolving pulp made from wood. The fibers have higher quality in a number of areas: tensile strength in both wet and dry condition, dye absorption and in withstanding high abrasion.

Fibers made from Circulose pulp have a lot in common with cotton fibers. But are organic, sustainable and allow for a better use of the planet’s resources.

Recently, Levi’s® launches its most sustainable jeans ever, a garment made with organic cotton and Circulose®.

Comments by our Users

Be the first to write a comment for this item.